UMM TOOLING

Tool Making China

- 12 years of exported mold making experience

- 10+ engineers’ engineering team

- 95% on-time delivery

- 80% T1 success rate

- 1 Professional project team

Plastic Injection Mold

UMM started to make export molds from 2007, now 80% of our molds are imported to Europe and America. Both quality and price are trusted by our clients. The max tool size is 1500x1200mm and the main industries of our molds are automotive, electronics, small home appliances and industrial.

We have a experienced engineering team: we make DFM (design for manufacturing) for each part before mold design, in this way we can pick the design problems in clent’s design and help clent’s mechnical engineer optimize the design of the part. For some complex parts or request shortest cycle time or excellent surface, we must make mold flow analysis to get best gate sizes and locations, molding process parameters etc..

- Mold Standards: LKM,DME,HASCO,MISUMI,MEUSBURGER…

- Hot Runner Partners: YUDO, MOLDMASTER, INCOE, HASCO, DME, HUSKY…

- Mold Steels: (M) H13, S136, NAK80, 1.2343, 1.2344, P20; (D) 1.2344, 8407, H13

- Plastic Material: ABS, ABS+PC , PC, PA/PA6+GF, POM, PAAM, TPU, TPE…

- Mold Size: Under 8 Tons ( 1500mm*1200mm)

- Industries: Auto Parts, Home Appliances, Electronic Products, Industrial Parts

- Mold Type: General Molds, Hot Runner Molds, 2K Molds, Over Molding

Over Mold & Insert Mold

Over mold: some people also call it double color (2K) or double shoot mold. The 2-color part usually made of 2 materials, one hard plastic inside and one soft plastic injection molded outsie. This part has two ways to make it. The easy way is to make 2 independent molds, during the molding process, firstly we injection the hard part for a batch using 1st mold, secondly put the hard part into 2nd mold to injection the soft plastic. The other and efficient way to make a twin molds and injectin in the double-shoot injection machine, the part made by this way has better precision usually.

Insert Mold: usually, the insert part is metal, such as copper nuts or stamping parts or die casting parts or machining parts. For insert part, we only need to make one mold and injection molding in common injection machine. The different is we need to put the insert part into the mold before molding.

UMM has engineering capacity and manufacturing experience in both over mold and insert mold.

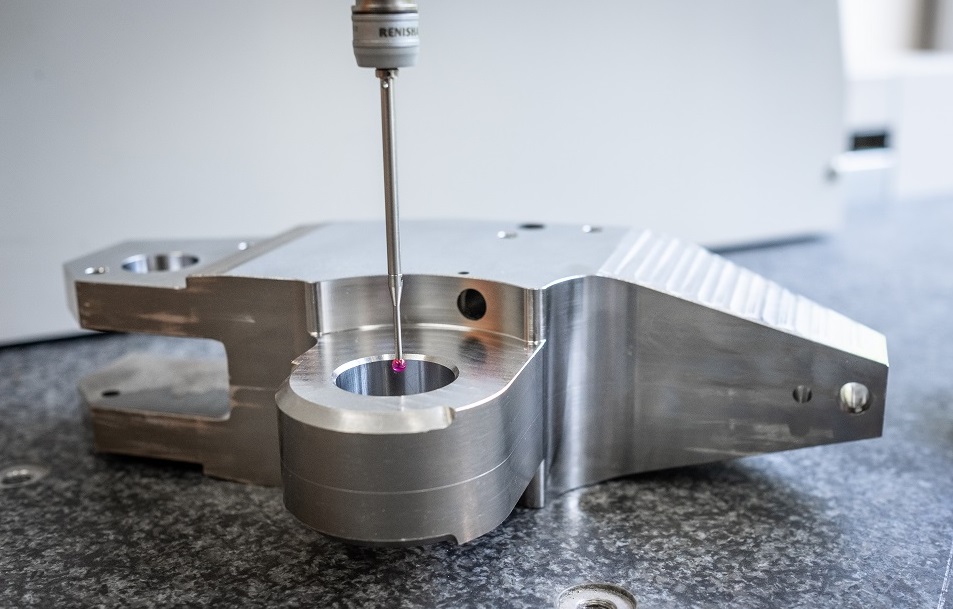

Our Quality

UMM has thorough quality system that under ISO 9001:2015 certifited. We check the incoming steel to make sure the source. Each key dimension is measured by our quality department using 3D CMM during the whole tooling process. We provide First Article Inspection report (FAI report) to prove the mold we made is what the client requested. What’s more, we check every details incliding water leakage test, components, anti-rust paint, packing etc to make sure our molds arrive to client safely.